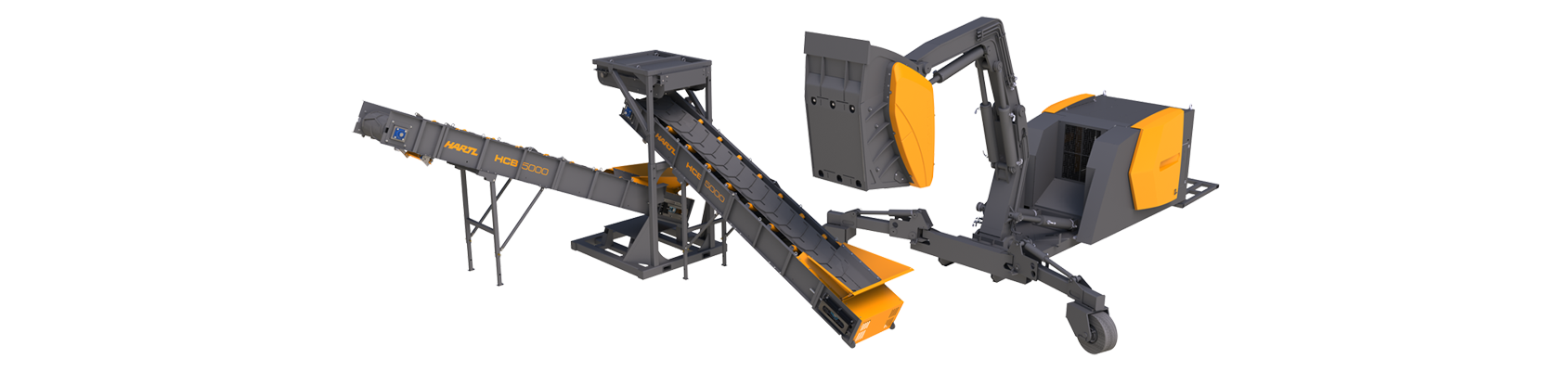

The HARTL CTR - Concrete Tie Recycler

is the most advanced and cost-effective solution for recycling railway sleepers with recycling rates in excess of 100 concrete ties per hour. The plant consists of the crushing unit E-CRUSHER, the PERFORMANCE SKID, the permanent magnet separator MAGNET TOWER and two conveyor belts.

Features

E-CRUSHER

The all-electric jaw crusher is based on the QUATTRO crushing movement developed by Hartl, has an automatic return function and unlocking integrated, guaranteeing a clean metal and high-quality cubic end grain of the recycled concrete.

PERFORMANCE SKID

The design ensures a stepless height adjustment of the crusher and thus can vary the discharge height under the crusher flexible. Long iron and steel strips can thus go through the recycling process without blockages. A tilt function via remote control is integrated. The easy transportability with hooklift trailer guarantees maximum mobility.

MAGNET TOWER

The permanent magnet sorts out 100% of the steel after crushing. The compact retractable construction makes the tower easy to transport and set up.

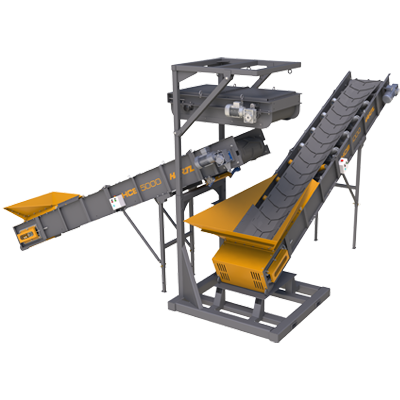

CONVEYOR BELTS

The collapsible conveyor belts are electrically driven, designed as standard with climbing belt and good discharge height. Optional screeners with one or two decks can ensure further separation into the desired final grain sizes.

CTR - Concrete Tie Recycler