THE CONCEPT

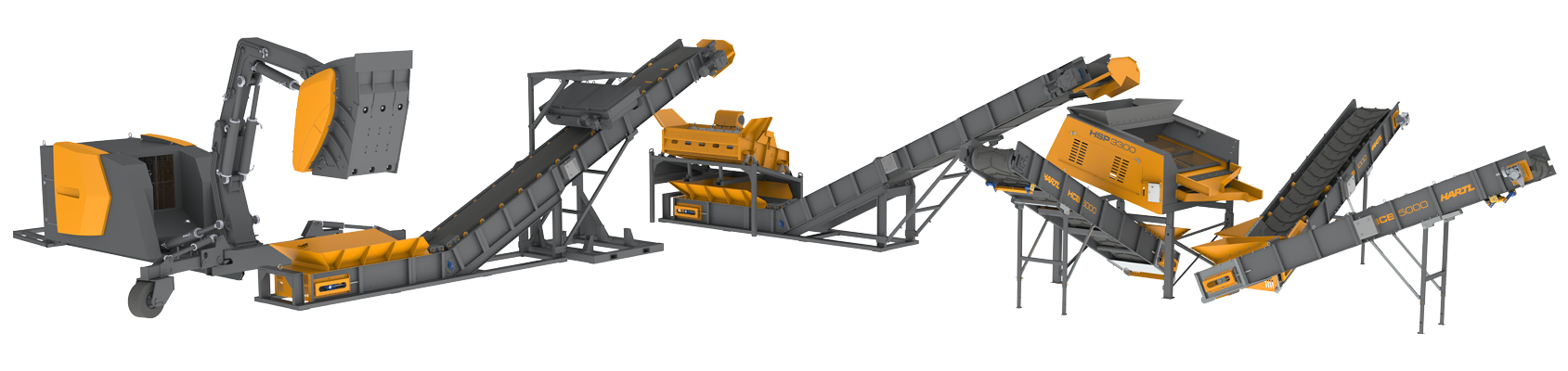

HARTL MODULAR SOLUTIONS is based on the idea of offering standardized modules for processing technology. Energy-efficient drive solutions, compact design with optimum transport dimensions and low dead weight guarantee maximum mobility and flexibility combined with high production output and low operating costs. Innovative, mature and partly patented technologies in the field of crushing and screening technology are guaranteed by the many years of experience of the HARTL family.

THE SOLUTION

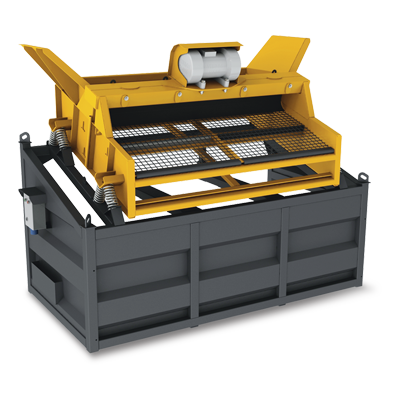

With our modular and mobile crushing and screening plants, every user can assemble his own individual processing plant - in a modular system - according to his needs. You only invest in what you really need. Whether in the processing of natural stone or in recycling - there is a suitable solution for every need with the corresponding modules - which are compactly designed and can be set up or set up quickly.

Features

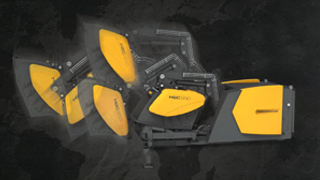

E-CRUSHER

Fully electric breaker, powered by 2 synchronous motors, each 25KW, combined with solid flywheels.

Quattro inside

The unique upward positioning of the toggle plate creates the incomparable QUATTRO movement. The movement of the movable jaw runs here, not parallel to the direction of passage, as in conventional crushers, but in an alternating rocking motion. This causes a Vorbrechen in the upper and a Nachbreching in the lower part of the crushing chamber. This allows larger chunks to be picked up and broken. The movement conveys the material downwards, thereby achieving maximum throughput.

Reverse Crushing

The HARTL E-CRUSHER has an automatic REVERSE FUNCTION and release integrated as standard, which in case of a blockage allows the crusher to run backwards, thus providing a quick solution to the blockage. This allows 100% uninterrupted working!

Fully Mobile

Low overall weight, container-sized dimensions and the construction on a standardized rolling frame for hook lift trailers guarantee easy and, above all, cost-effective transport.

Modular Solutions